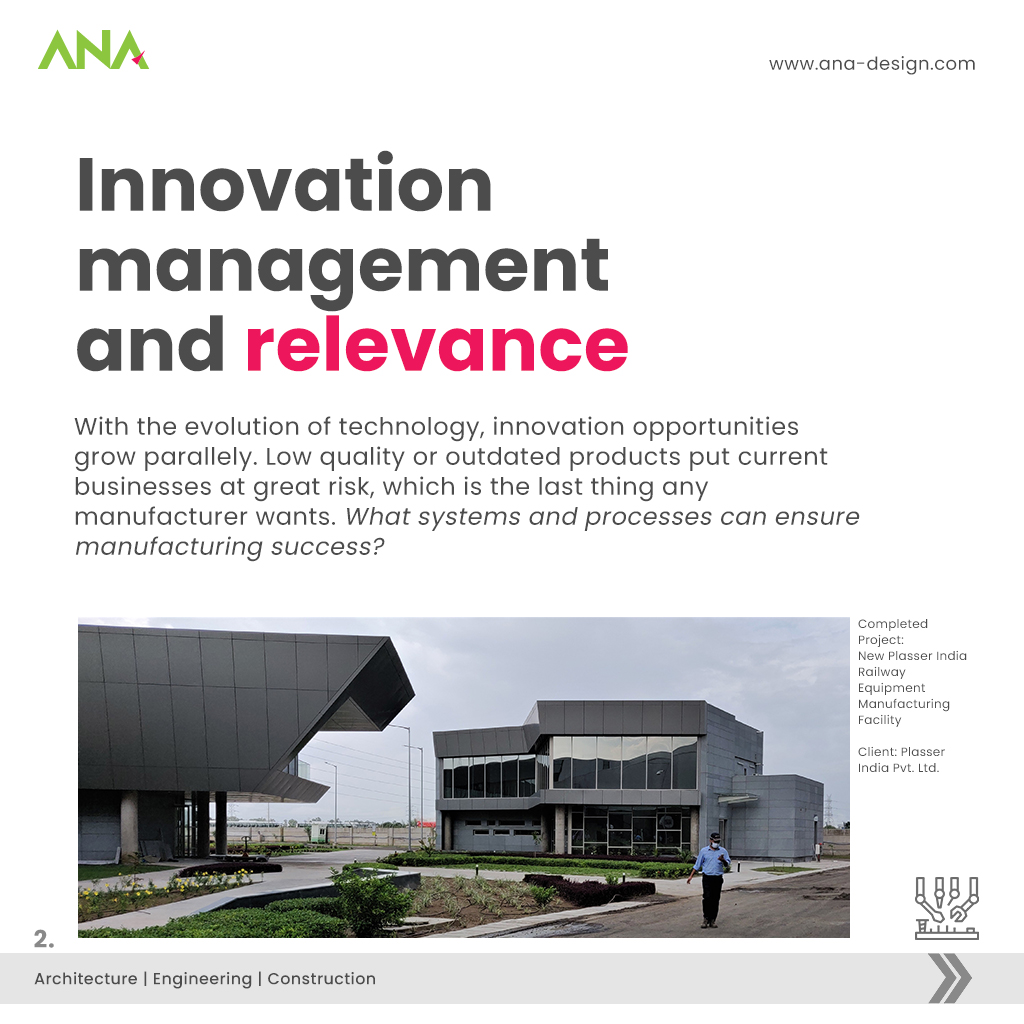

Innovation management and relevance.

With the evolution of technology, innovation opportunities grow parallelly. Low quality or outdated products put current businesses at great risk, which is the last thing any manufacturer wants. What systems and processes can ensure manufacturing success?

Management of skill gaps.

Manufacturers often face challenges in attracting and retaining high skilled workers. With a new generation emerging, the need for upskilling is more than ever. One way is to work with the education sector to train workers from time to time. What other strategies can be employed?

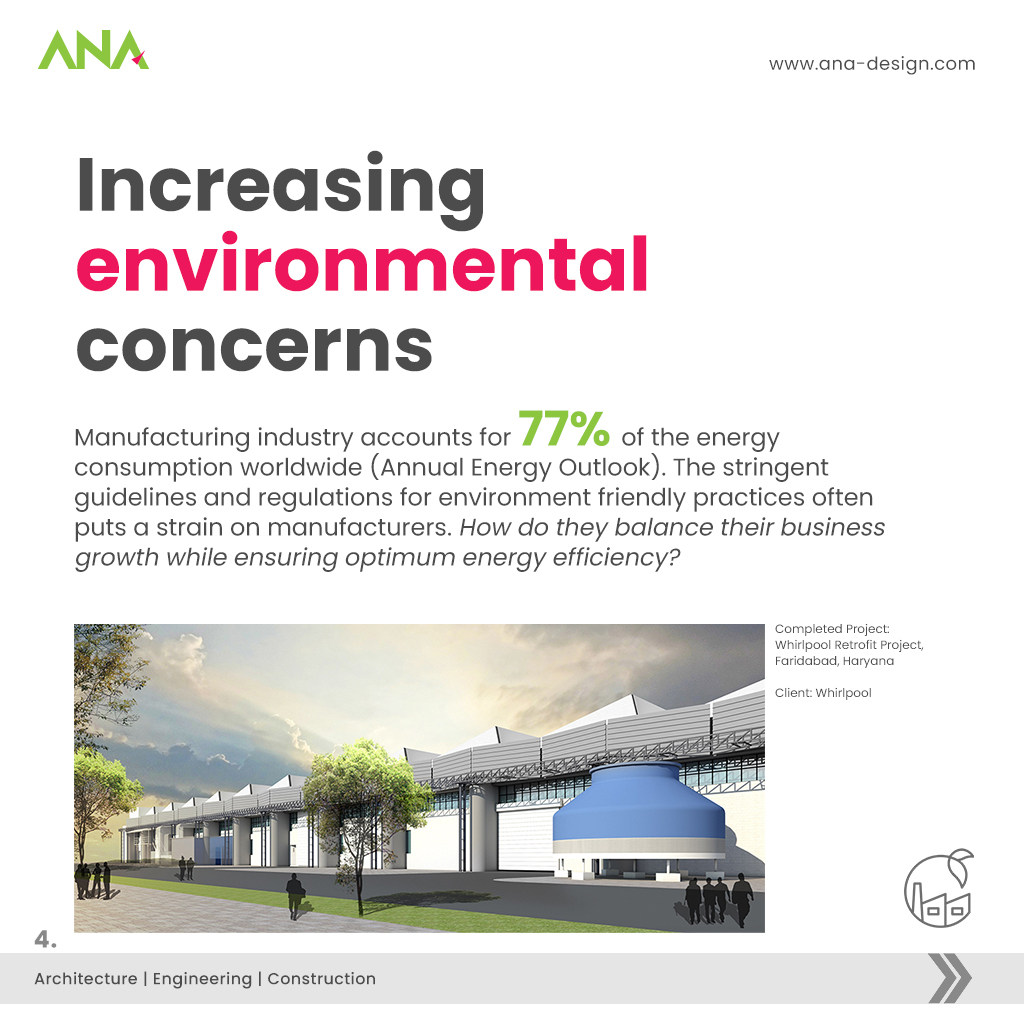

Increasing environmental concerns.

Manufacturing industry accounts for 77% of the energy consumption worldwide (Annual energy outlook). The stringent guidelines and regulations for environment friendly practices often puts a strain on manufacturers. How do they balance their business growth while ensuring optimum energy efficiency?

High production, manufacturing and operational costs.

Right from procurement of raw material to maintenance cost of processes within the industry, all impact the overall financials of the company. Many industries have adopted strategies such as cost optimized product design, lean manufacturing principles, and standardization to reduce overall costs. In what other ways can costs be optimized?

Will high performance industrial buildings help resolve some of these challenges?

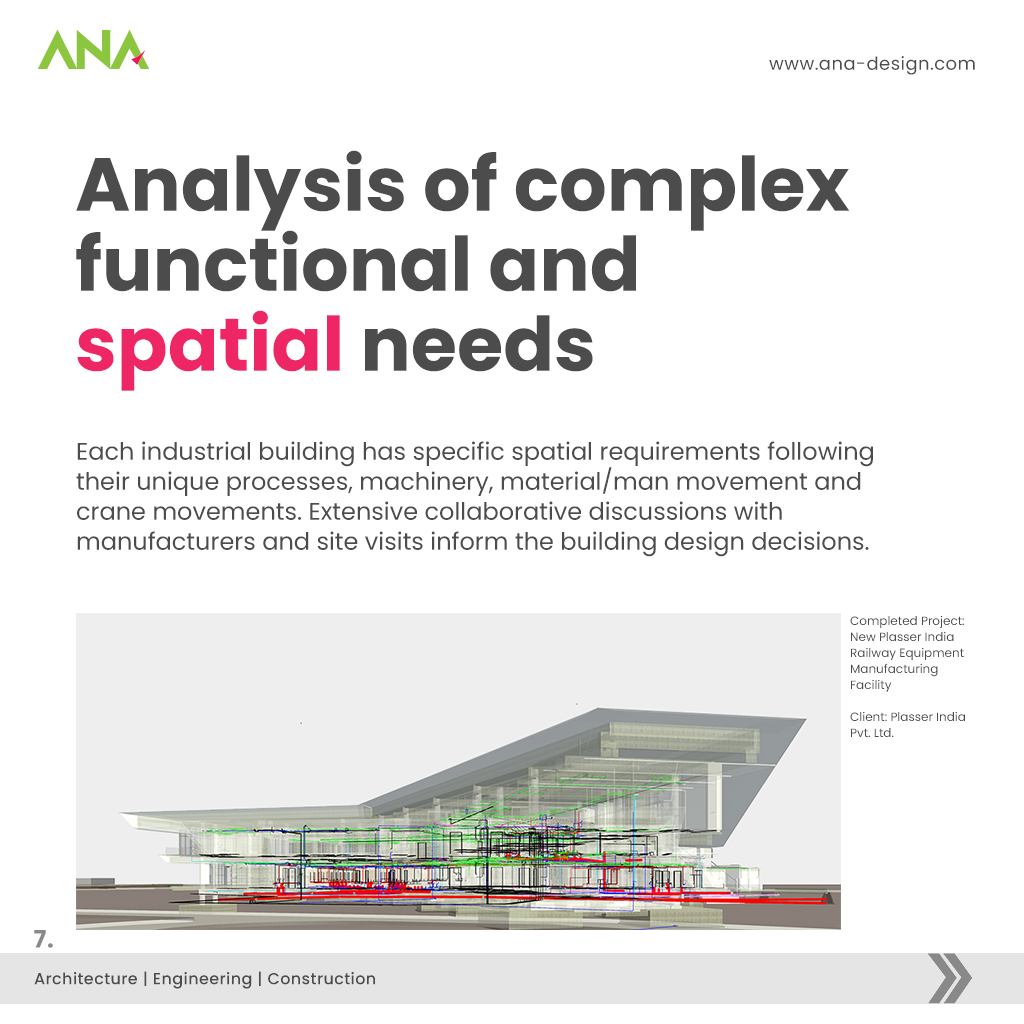

Analysis of complex functional and spatial needs.

Each industrial building has specific spatial requirements following their unique processes, machinery, material/man movement and crane movements. Extensive collaborative discussions with manufacturers and site visits inform the building design decisions.

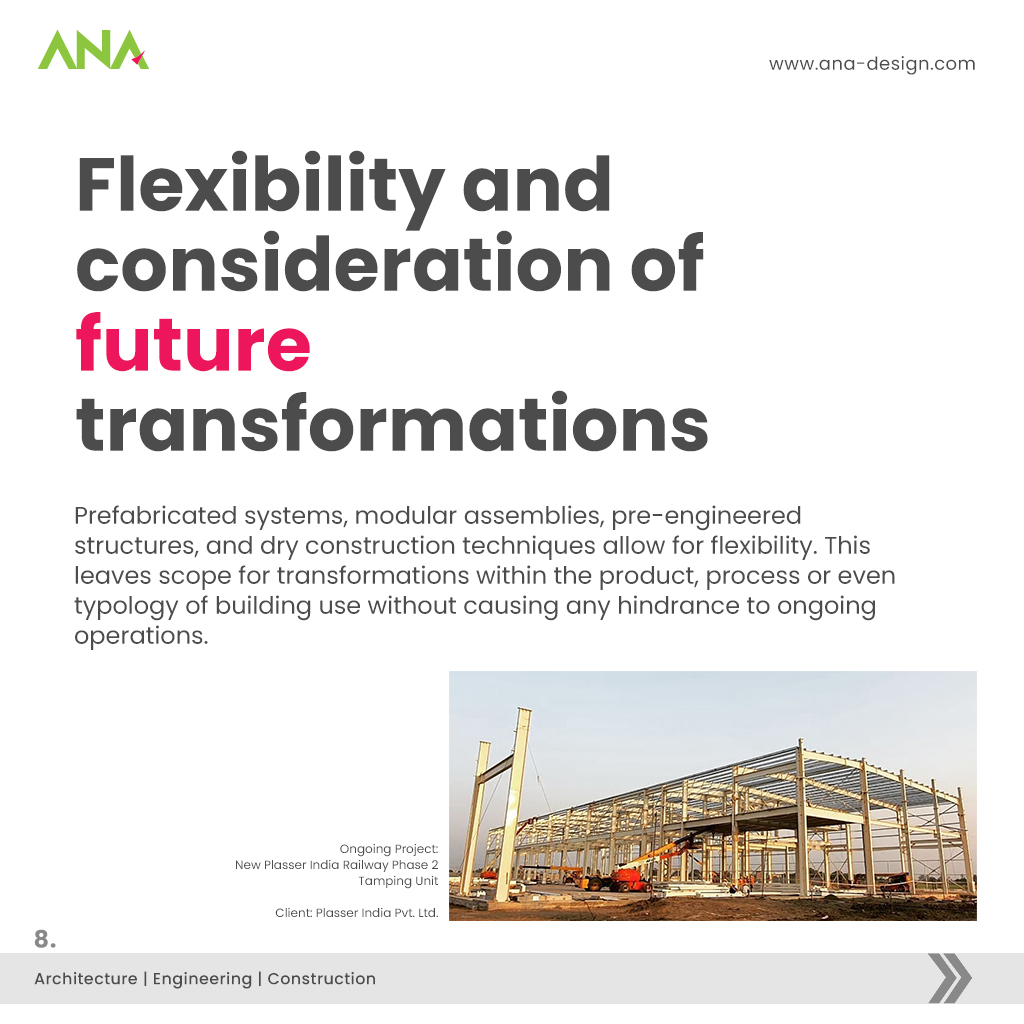

Flexibility and consideration of future transformations.

Prefabricated systems, modular assemblies, pre-engineered structures, and dry construction techniques allow for flexibility. This leaves scope for transformations within the product, process or even typology of building use.

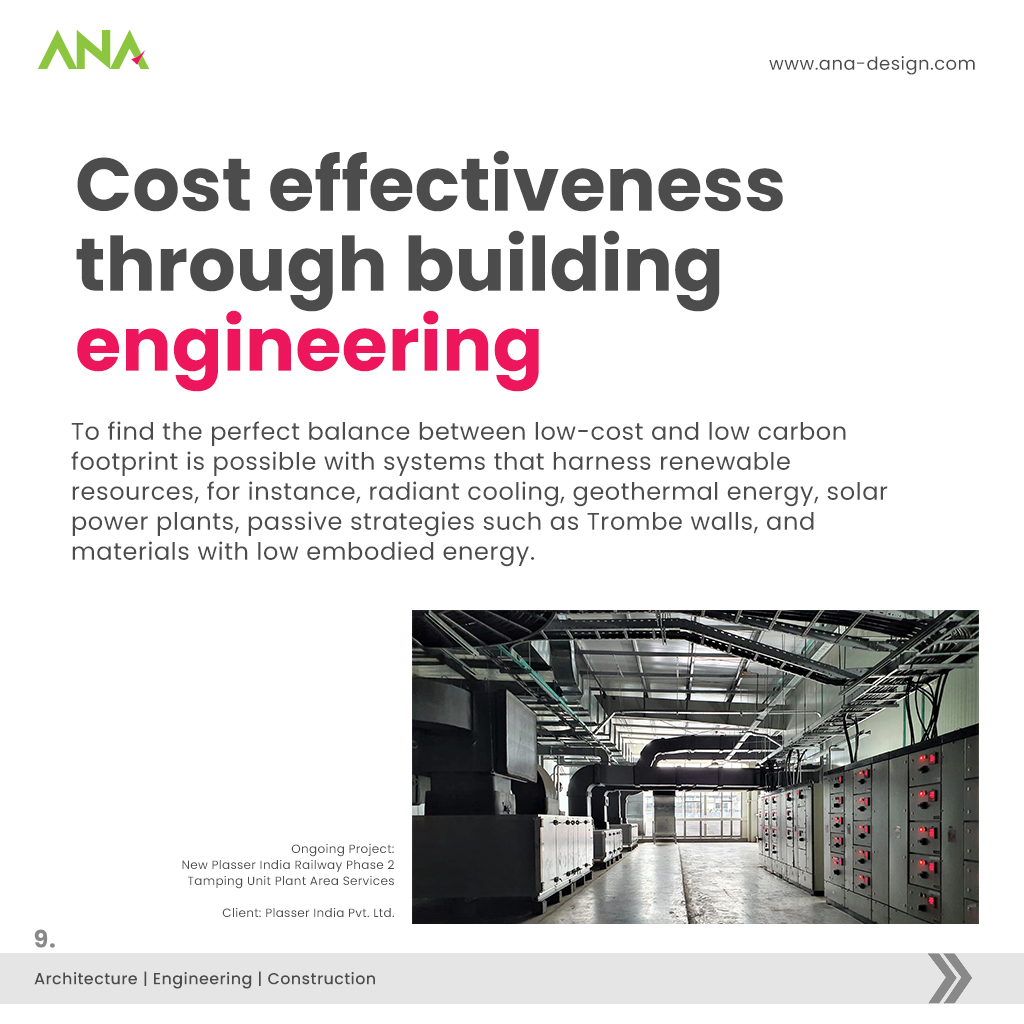

Cost and energy efficient solutions.

To find the perfect balance between low-cost and low carbon footprint is almost possible with systems that harness renewable resources, for instance, radiant cooling, geothermal energy, solar power plants, passive strategies such as Trombe walls, and materials with low embodied energy.

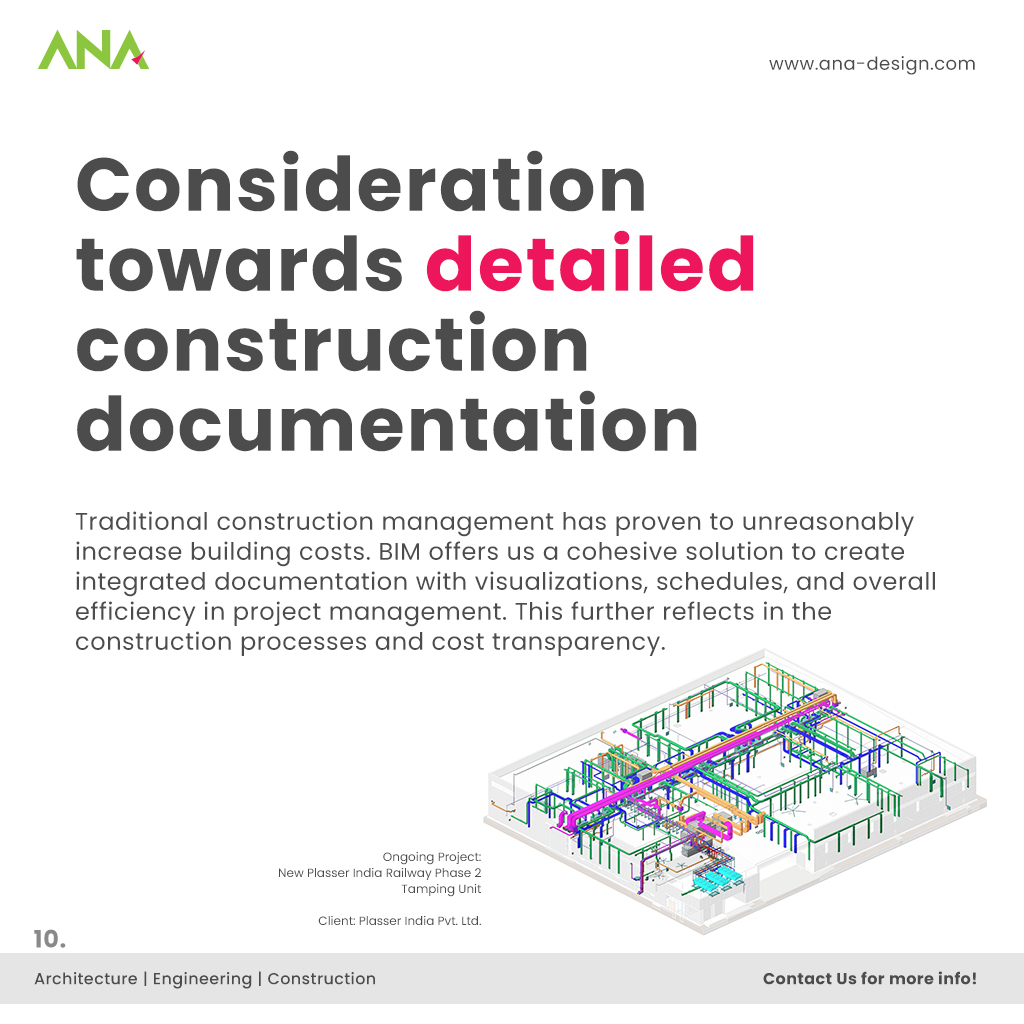

Consideration towards detailed construction documentation.

Traditional construction management has proven to unreasonably increase building costs. BIM offers us a cohesive solution to create integrated documentation with drawings, visualizations, schedules, bill of quantities, and overall efficiency in project management. This efficiency further reflects in the construction processes and further in overall infrastructure cost.

Great piece of writing with immensely informative contents! I really liked the writing style and the whole process of the story building. Waiting for more posts! Cheers!!

Thankyou! We are coming up with more such articles. Stay Tuned!