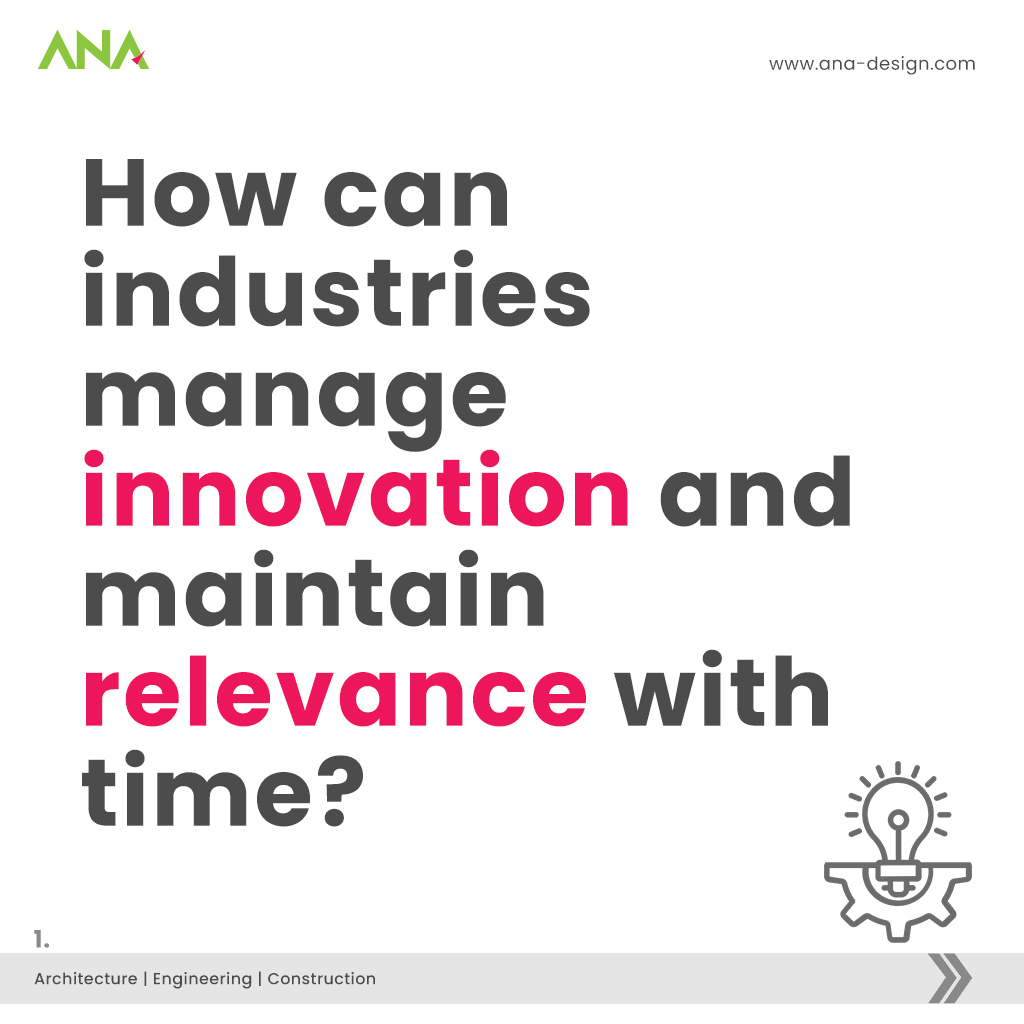

Responding to pandemics

The recent pandemic COVID-19 has disturbed industries in almost every sector with supply chain disruptions. Within a changed economic landscape, manufacturers are adapting by shifting to local markets creating ‘reshoring’ opportunities, safety/hygiene practices. Integrating non-hosting surfaces within premises, and improved indoor air quality via a mix of natural and mechanical ventilation is the way forward.

Growing with increasing demand

Manufacturing has emerged as one of the high growth sectors in India. With a growing demand, manufacturers need to scale up their processes, investments, strategies and production facilities. How do they cope up and adapt to the ever-changing demands?

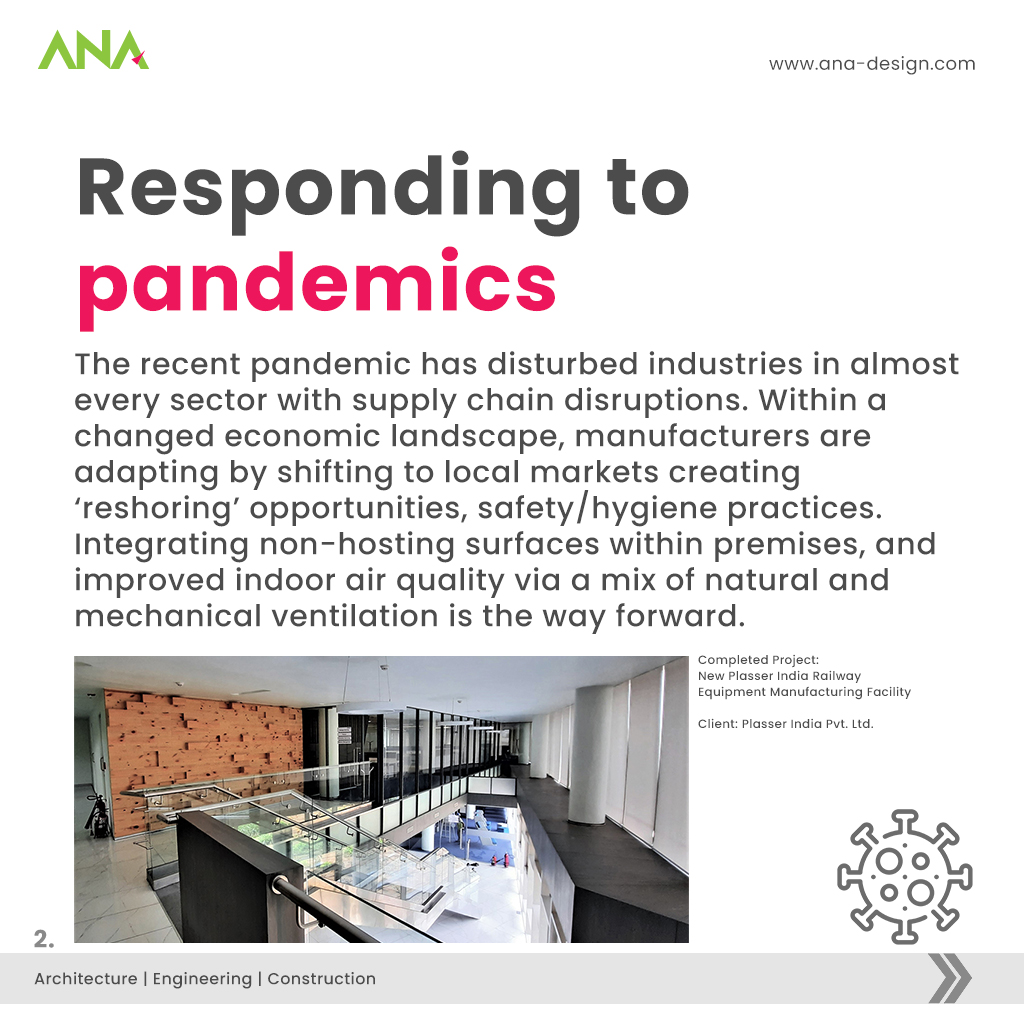

Handling global competition

With globalization on the rise, it’s important for manufacturers to pay extra attention to quality control and management. This can be further aided by high quality built environments for both indoors and outdoors of a manufacturing facility. Industrial environments should be designed for the well-being of its employees, not just for the machines.

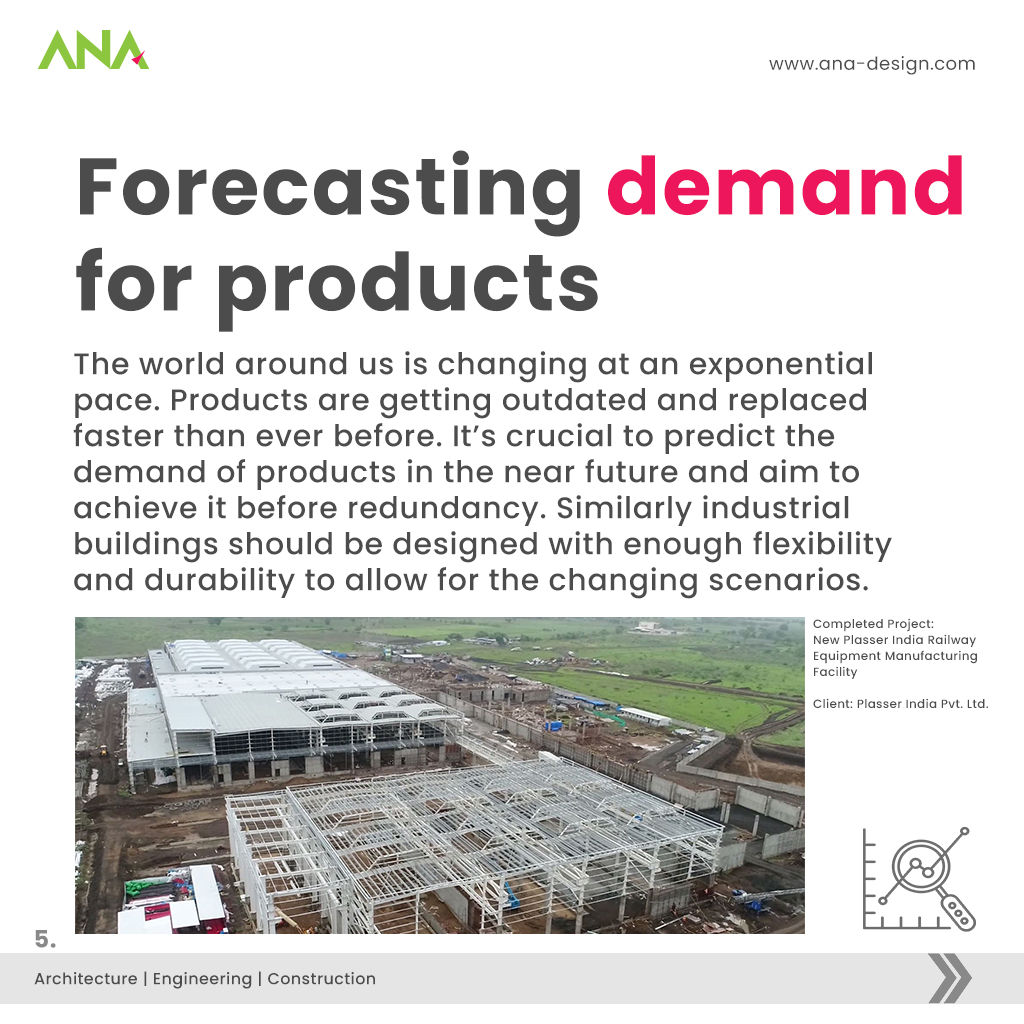

Forecasting demand for products

The world around us is changing at an exponential pace. Products are getting outdated and replaced faster than ever before. It’s crucial to predict the demand of products in the near future and aim to achieve it before redundancy. Similarly industrial buildings should be designed with enough flexibility and durability to allow for the changing scenarios.

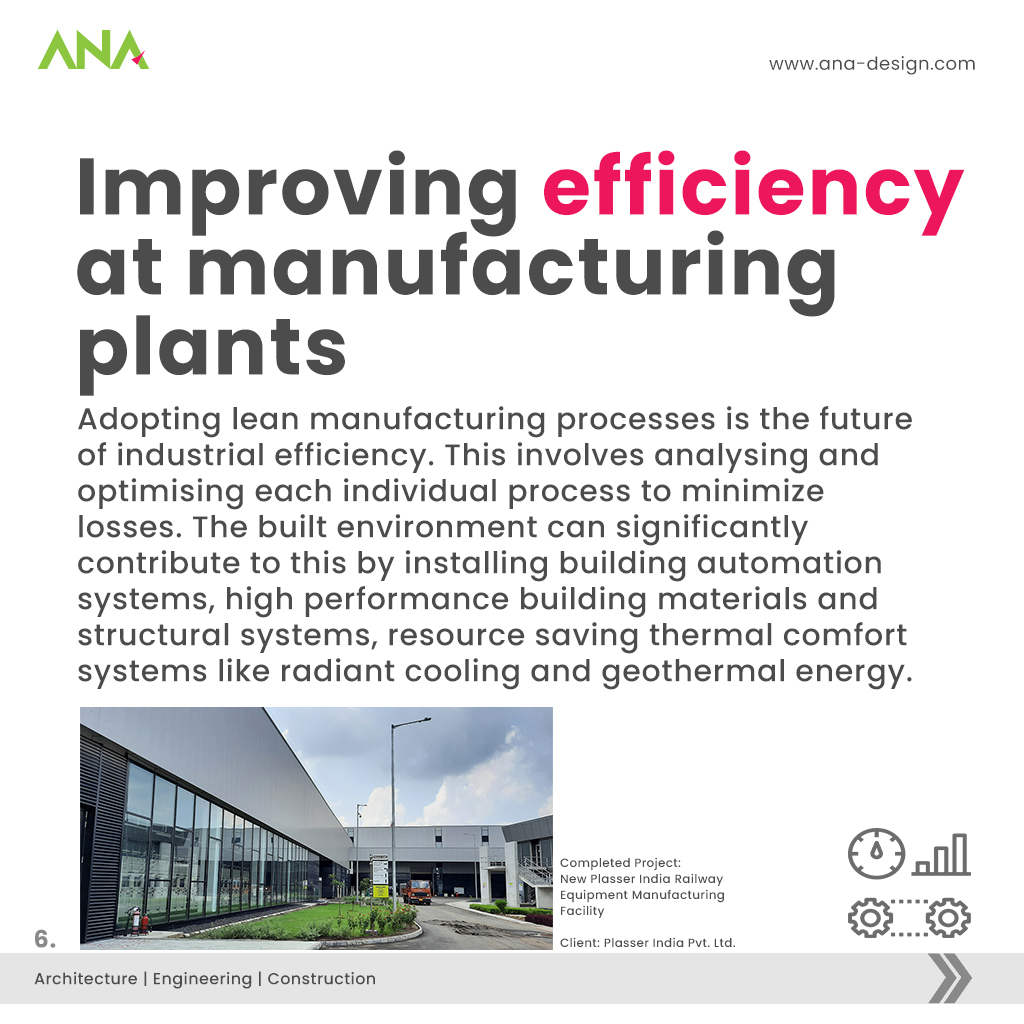

Improving efficiency at manufacturing plants

Adopting lean manufacturing processes is the future of industrial efficiency. This involves analyzing and optimizing each individual process to minimize losses. The built environment can significantly contribute to this by installing building automation systems, high performance building materials and structural systems, resource saving thermal comfort systems like radiant cooling and geothermal energy.

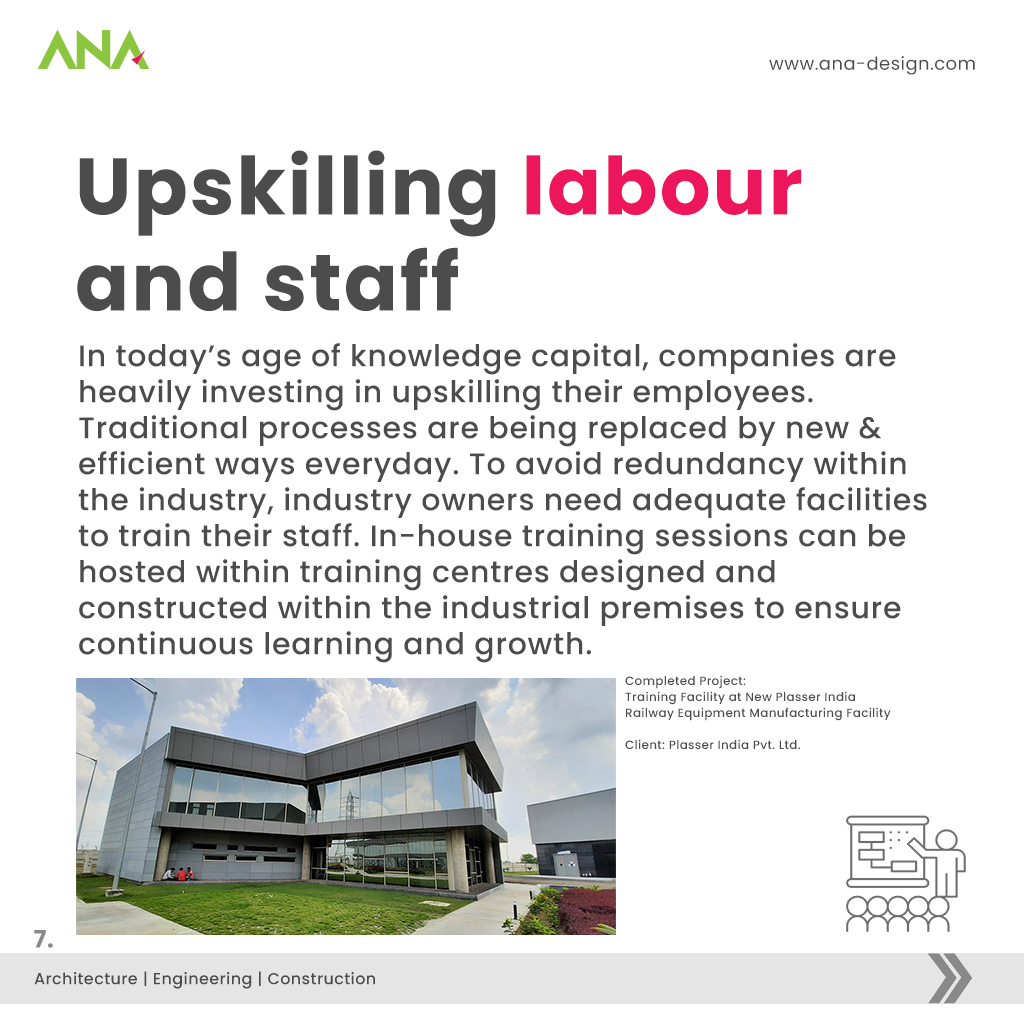

Upskilling workers & staff

In today’s age of knowledge capital, companies are heavily investing in upskilling their employees. Traditional processes are being replaced by new and efficient ways everyday. To avoid redundancy within the industry, industry owners need adequate facilities to train their staff. In-house training sessions can be hosted within training centers designed and constructed within the industrial premises to ensure continuous learning and growth.

Managing and controlling inventory

Inventory management has come a long way since the industrial revolution. Adequate flexible space for goods loading, unloading, storage, and distribution is the pre-requisite for a production facility. We need to ensure high indoor air quality for storage spaces, comfortable traffic management for loading/unloading docks, and high performance finishes for daily production activities.

Strategizing reshoring efforts

Disruptive global events like the recent pandemic have shifted company operations from offshoring to reshoring i.e. bring manufacturing back home from overseas. As industries strategize reshoring activities, they need to invest in much more sustainable (both financially and environmentally) industrial facilities amongst the growing industrial among the growing industrial zones.

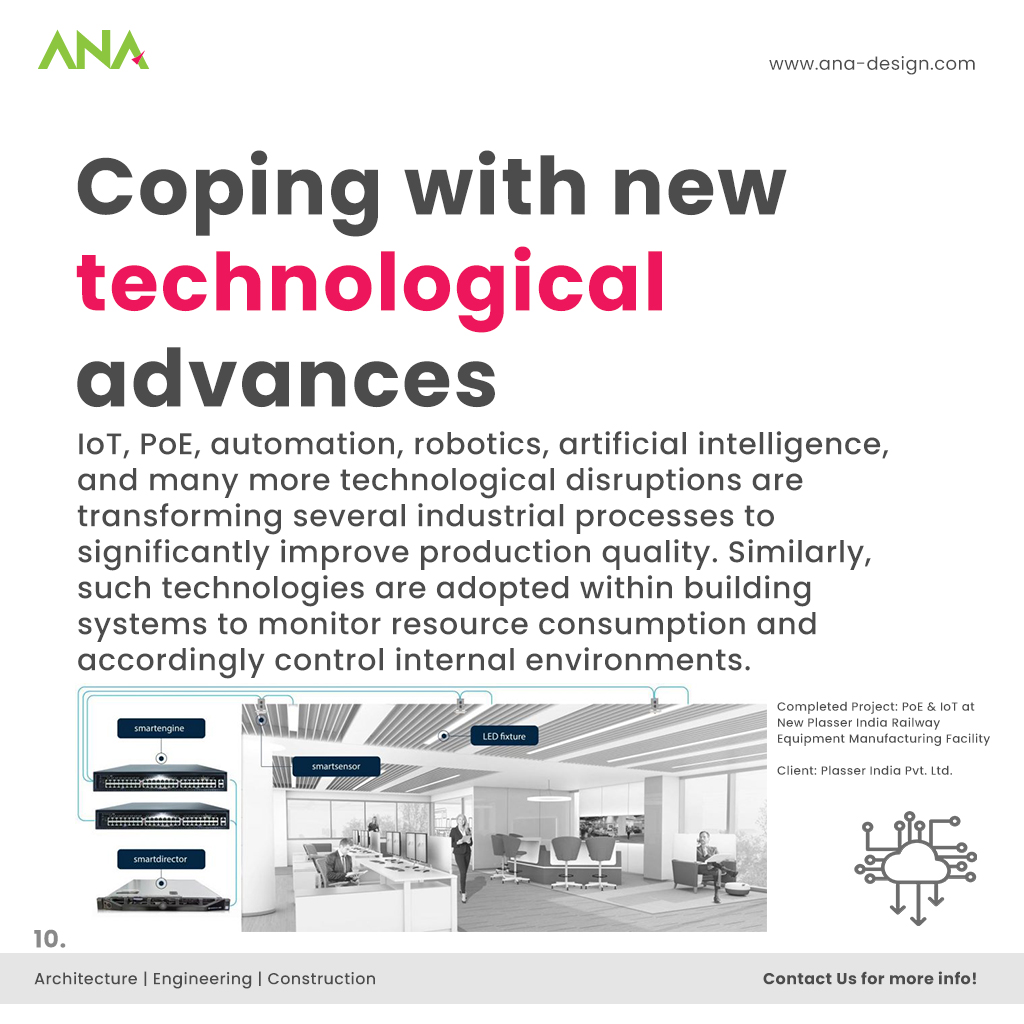

Coping with new technological advances

IoT (Internet of Things), PoE (Power of Ethernet), automation, machine learning, artificial intelligence, and many more technological disruptions are transforming several industrial process to significantly improve production quality. Similarly, such technologies are adopted within building systems to monitor resource consumption and accordingly control internal environments.