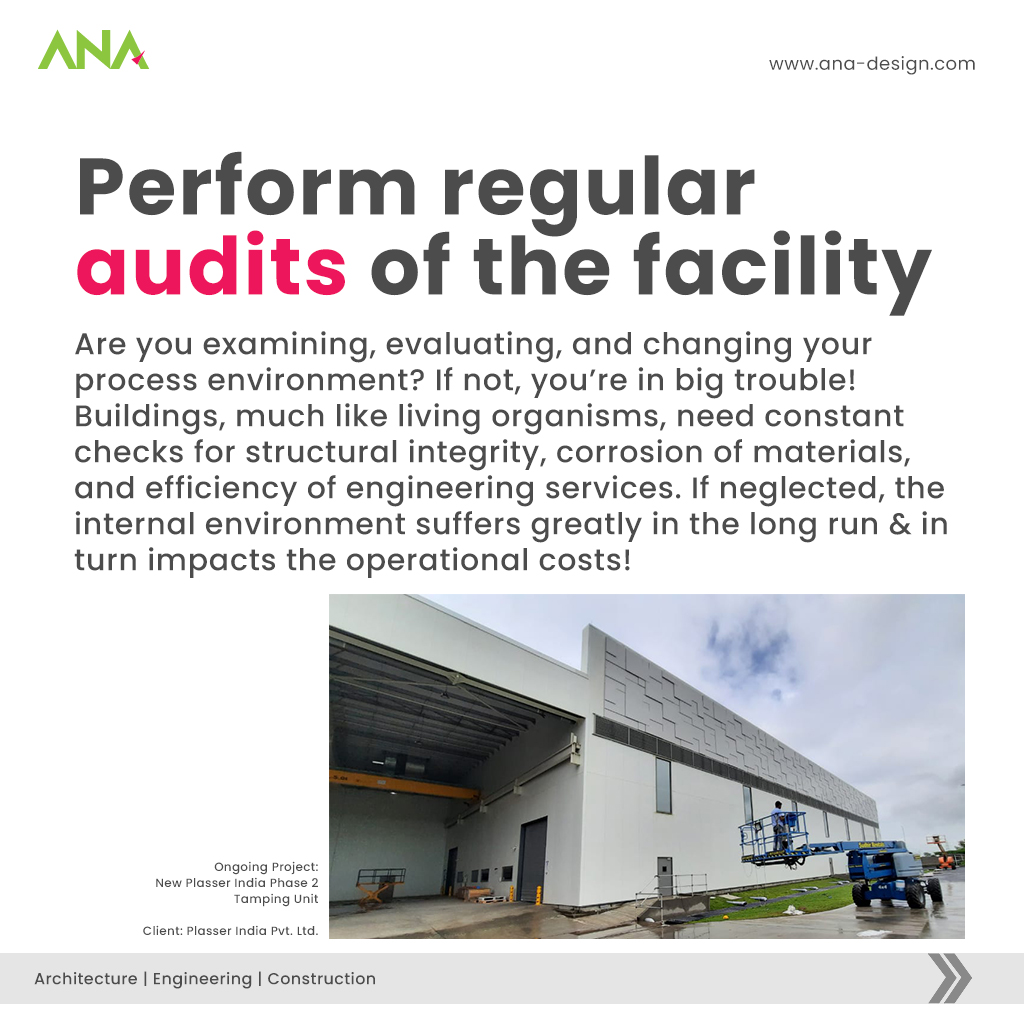

Perform regular audits of the facility

Are you examining, evaluating and changing your process environment? If not, you’re in big trouble! Buildings, much like living organisms, need constant checks for structural integrity, corrosion of materials, and efficiency of engineering services. If neglected, the internal environment suffers greatly in the long run and in trun impacts the operational costs!

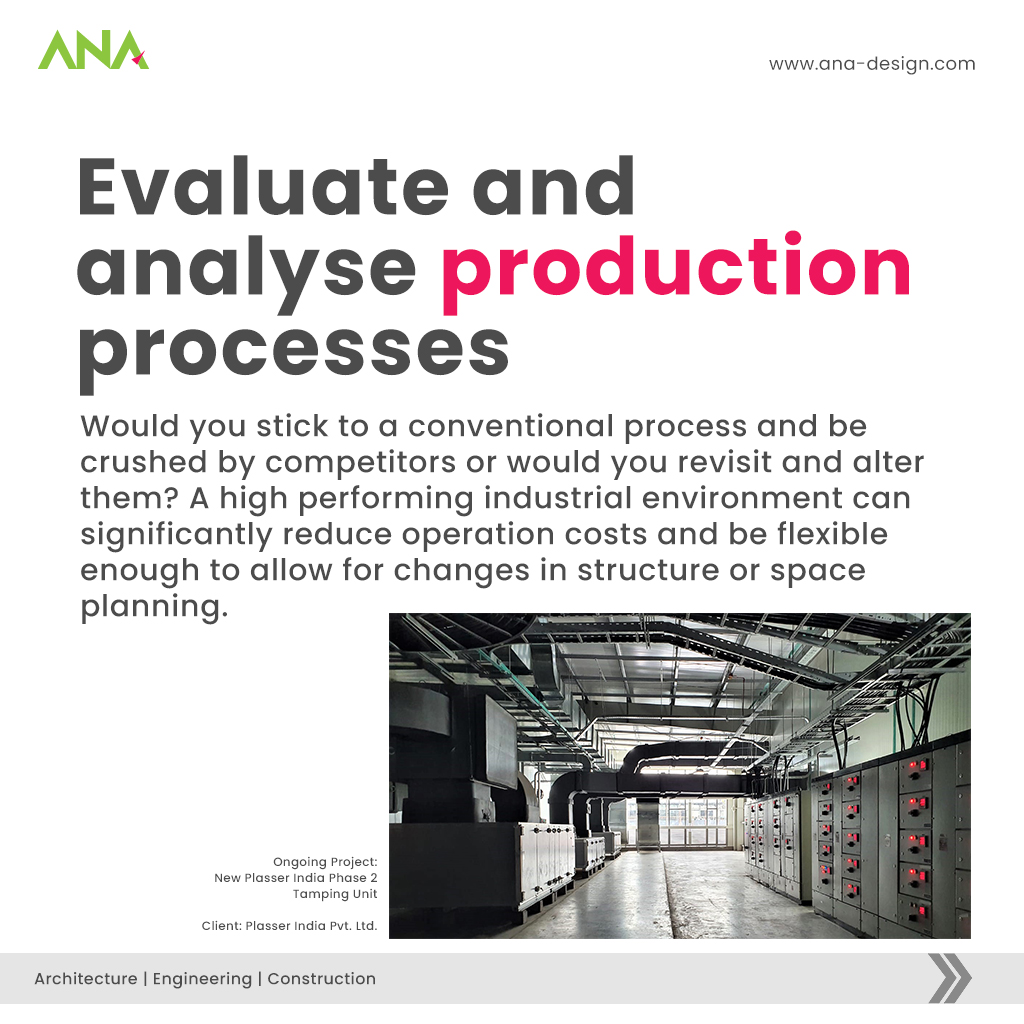

Evaluate and analyze production processes

Would you stick to a conventional process and be crushed by competitors or would you revisit and alter them? A high performing industrial environment can significantly reduce operational costs and be flexible enough to allow for changes in structure or space planning.

Optimize workforce efficiency

Unlike the industrial revolution era, modern skilled workers are not treated as inhuman labour working as machines in factories. Optimum thermal comfort, breakout spaces and lawns to relax, and high indoor air quality can significantly improve workforce productivity! This in turn reduces the OPEX of your industrial building.

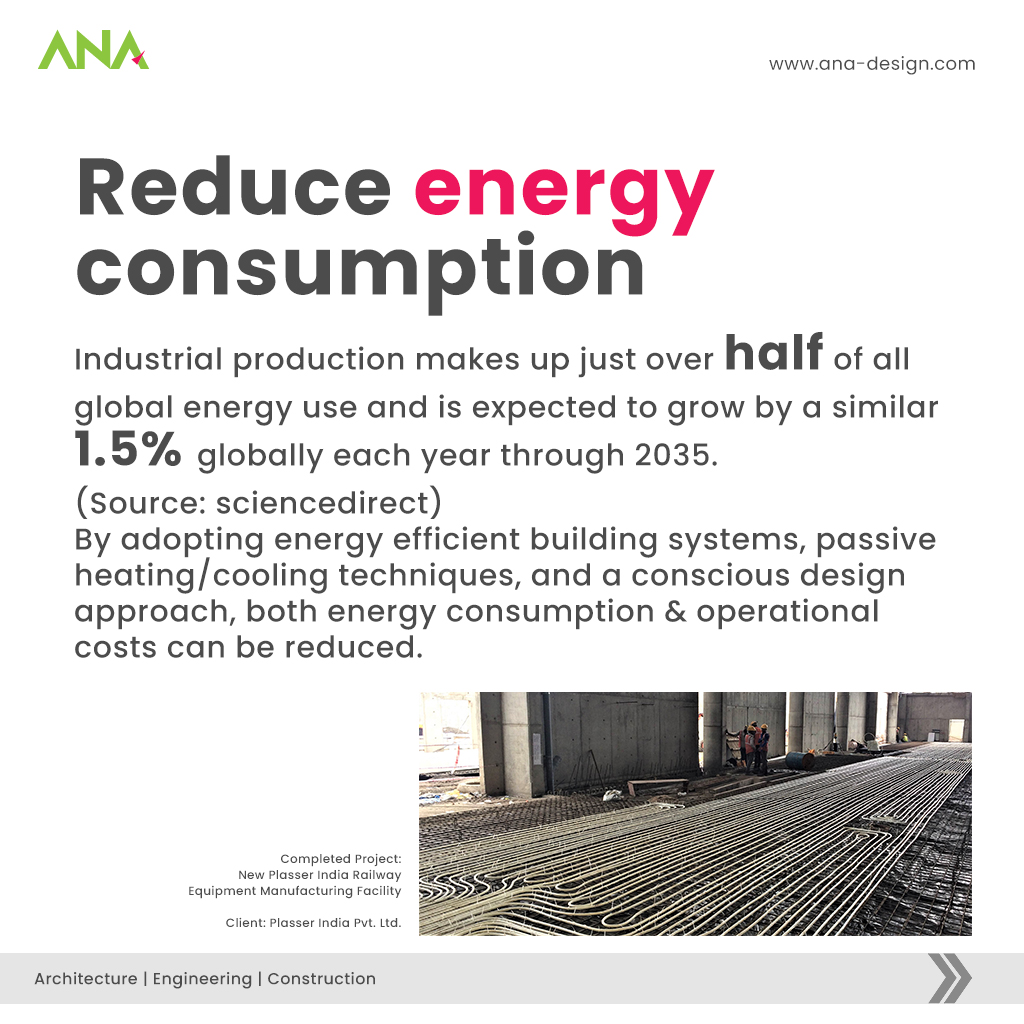

Reduce energy consumption

Industrial production makes up just over half of all global energy use and is expected to grow by a similar 1.5% globally each year through 2035. – Source: sciencedirect. By adopting energy efficient building systems, passive heating/cooling techniques, and a conscious design approach, both energy consumption and operational costs can be reduced.

Smart investments in smart technologies

There’s a paradigm shift visible in the process industry where robotics and automations are leveraged like never before. Building automation leverages a similar idea to monitor and control services like lighting, HVAC, fire-fighting and plumbing. This initial investment can be a massive cost saver in the long run

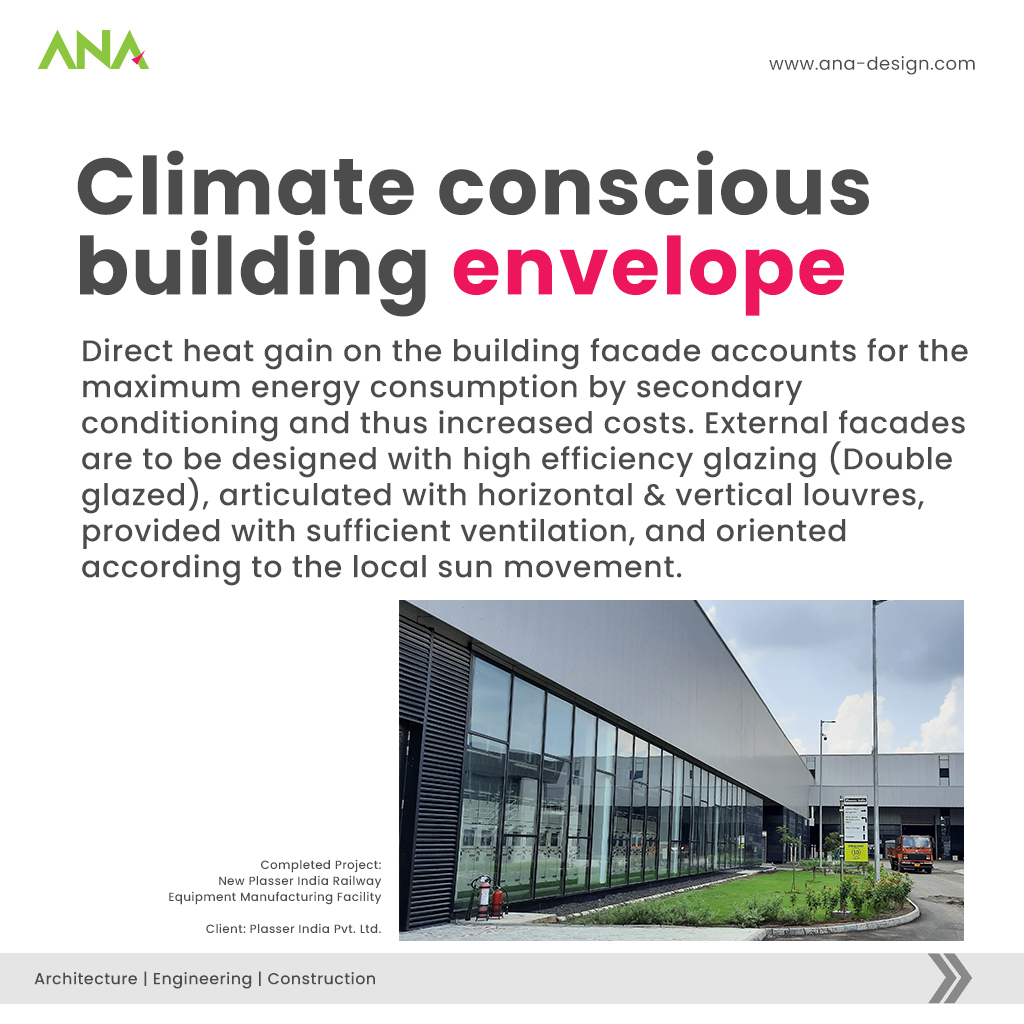

Climate conscious building envelope

Direct heat gain on the building façade accounts for the maximum energy consumption by secondary conditioning and thus increased costs. External facades are to be designed with high efficiency glazing (Double glazed), articulated with horizontal and/or vertical louvers, provided with sufficient ventilation, and oriented according to the local sun movement.

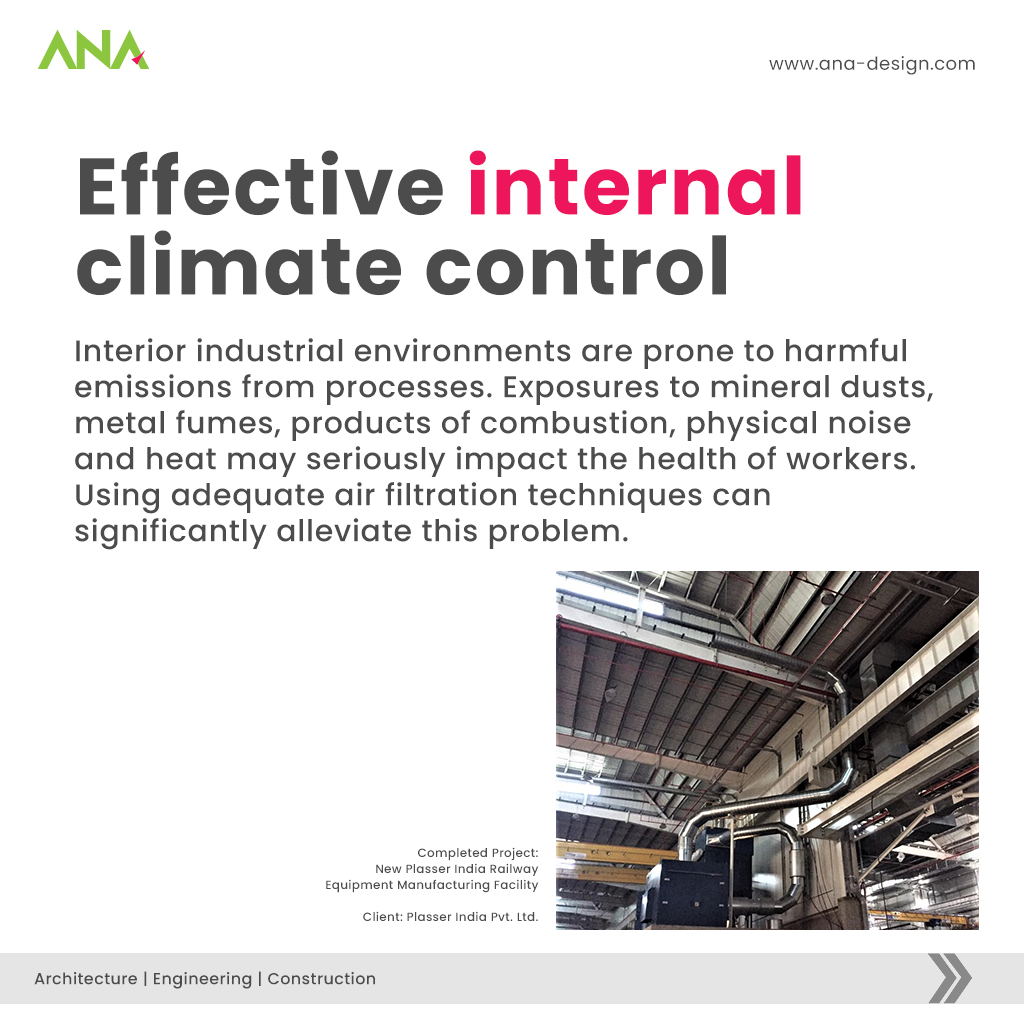

Effective internal climate control

Interior industrial environments are prone to harmful emissions from various processes. Exposures to mineral dusts, metal fumes, products of combustion, physical noise and heat may seriously impact the health of workers. Using adequate air filtration techniques can significantly alleviate this problem.

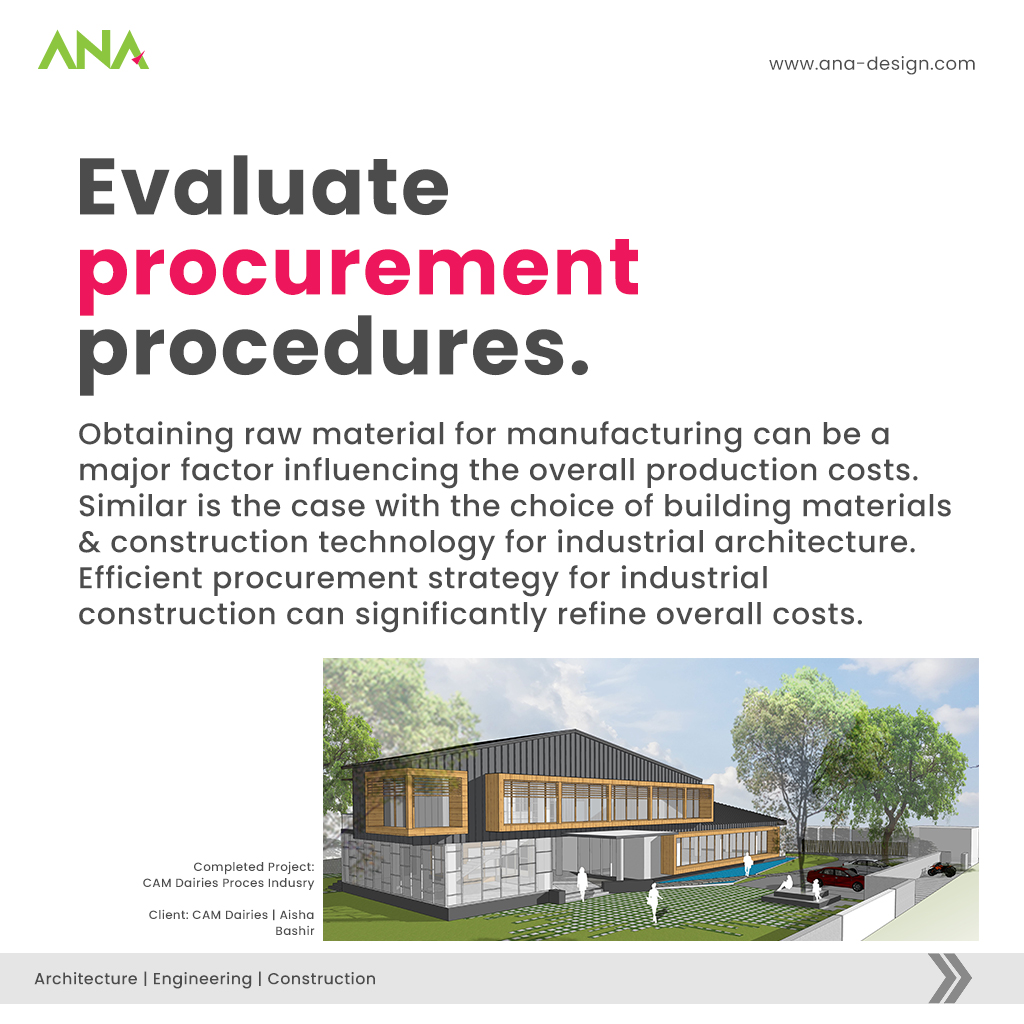

Evaluate procurement procedures

Obtaining raw material for manufacturing can be a major influencing the overall production costs. Similar is the case with the choice of building materials and construction technology for industrial architecture. Efficient procurement strategy for industrial construction can significantly refine overall costs.

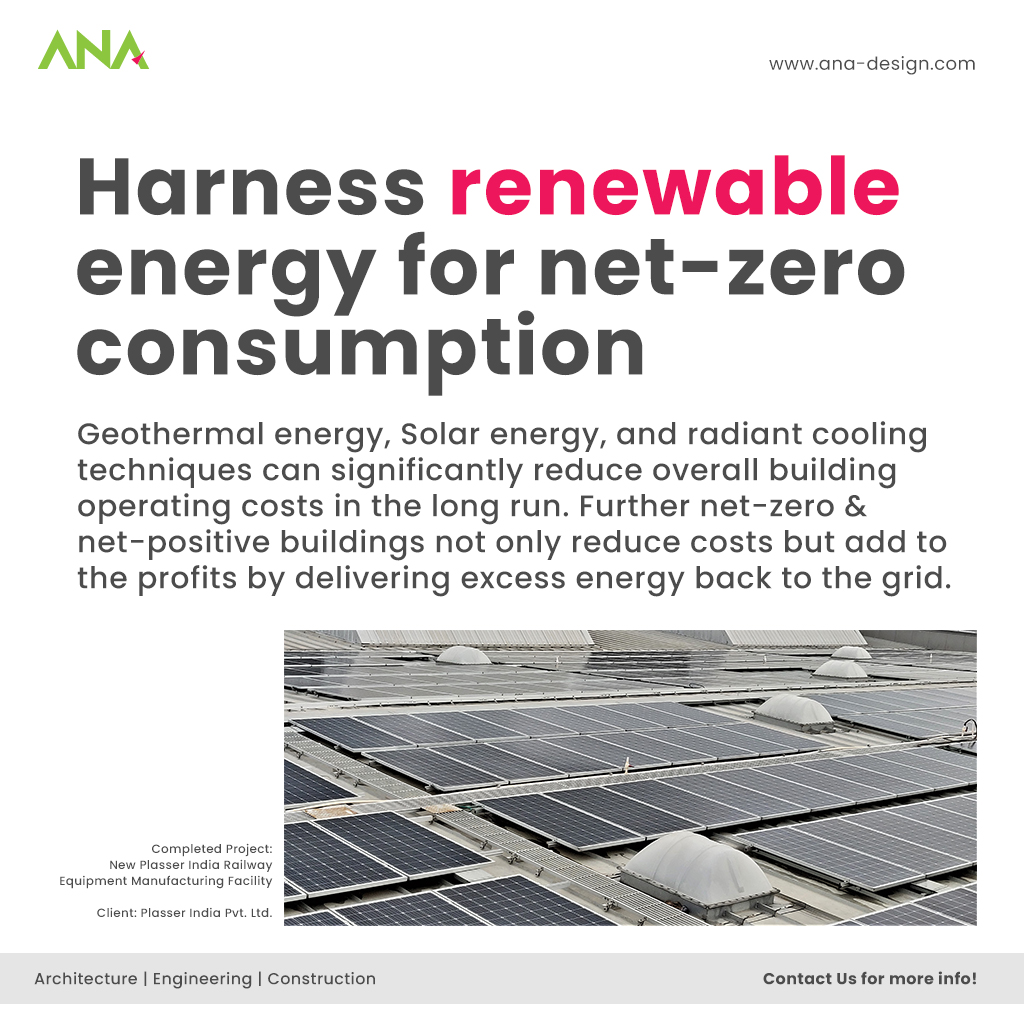

Harness renewable energy for net-zero emissions

Geothermal energy, solar energy, and radiant cooling techniques can significantly reduce overall building operating costs in the long run. Further net-zero and net-positive buildings not only reduce costs but add to the profits by delivering excess energy back to the grid.

really amazing post,Digital Marketing Agency in Hyderabad