and how we can help you bust the myths!

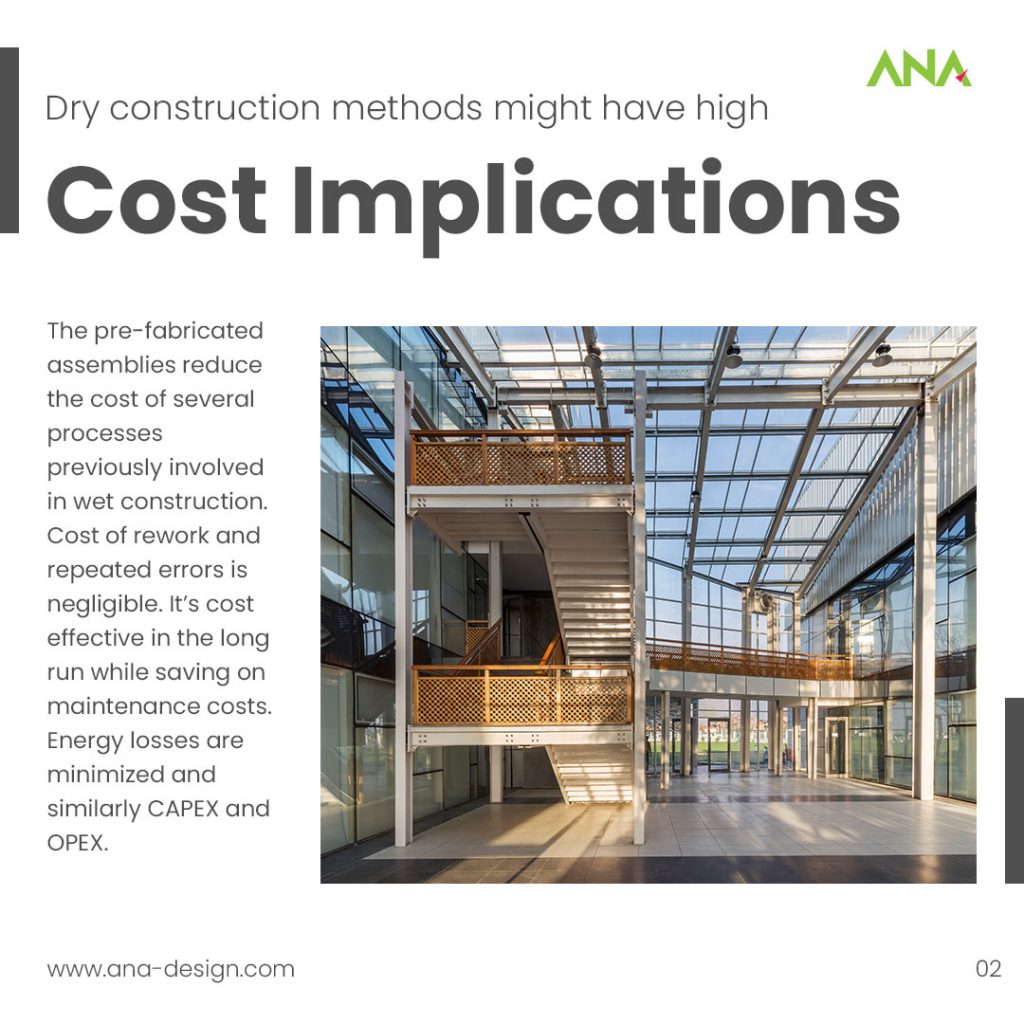

1. Dry Construction methods might have high

Cost Implications

The prefabricated assemblies reduce the cost of several processes previously involved in wet construction. Cost of rework and repeated errors is negligible. It’s cost effective in the long run while saving on maintenance costs. Energy losses are minimized and similarly CAPEX and OPEX.

2. Dry Construction methods might not be a

Valuable Market

According to Market Research Future (MRFR), the Global Dry Construction Market was valued at USD 79.7 billion in 2019, and it is expected to reach USD 102.8 billion by 2027 at 5.1% CAGR during the forecast period (2020-2027). FDI inflows in real estate and construction technology will only continue to rise over the coming years.

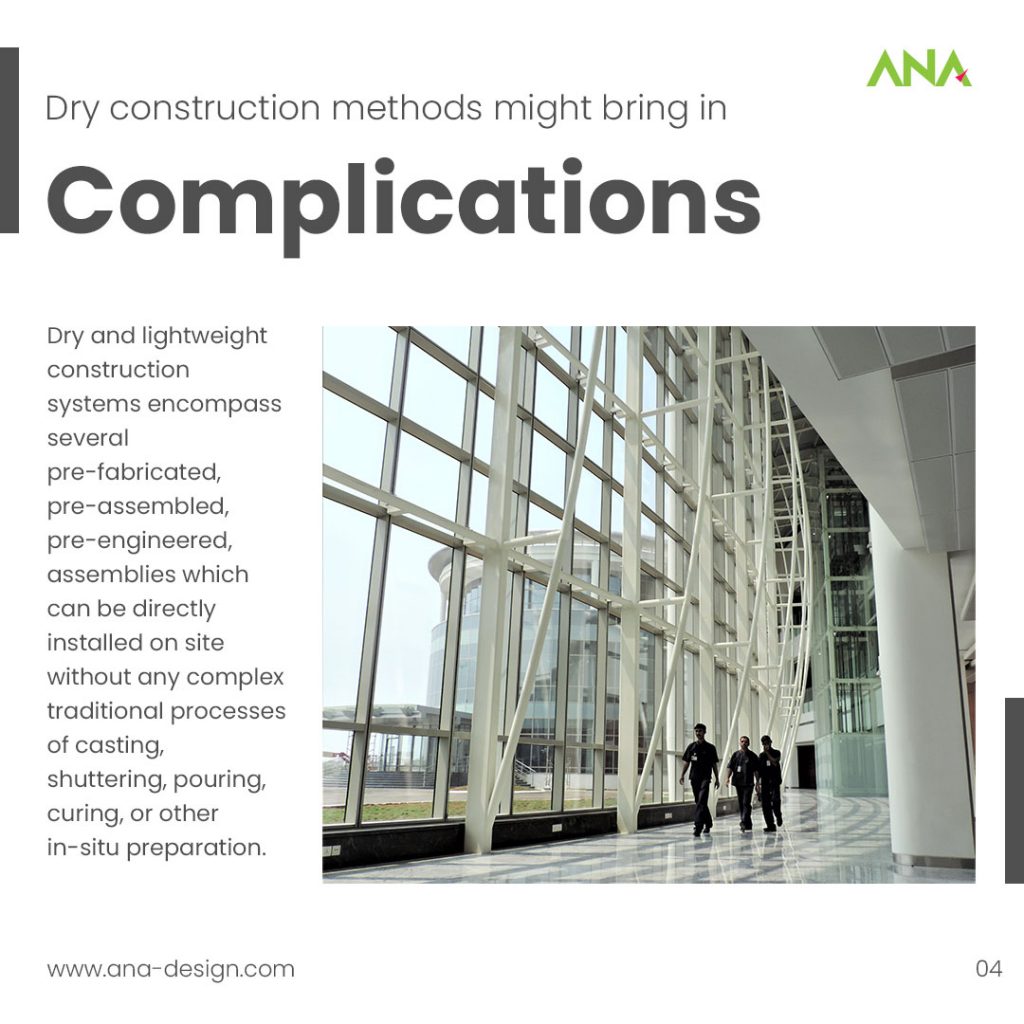

3. Dry Construction methods might bring

Complications

Dry and lightweight construction systems encompass several pre-fabricated, pre-assembled, and pre-engineered assemblies which can be directly installed on site without any complex traditional processes of casting, shuttering, pouring, curing, or other in-situ preparation.

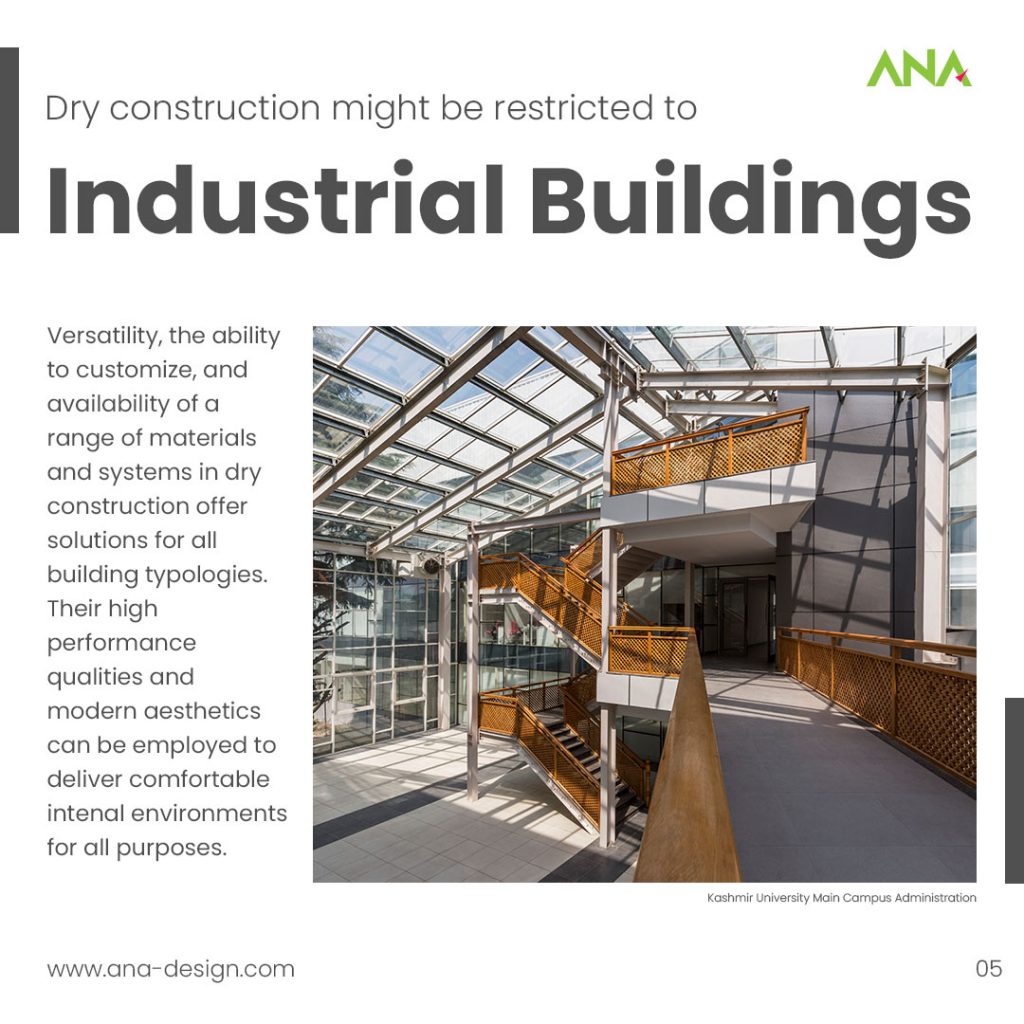

4. Dry Construction methods be Restricted to

industrial buildings

Versatility, the ability to customize, and availability of a range of materials and systems in dry construction offer solutions for all building typologies. Their high performance qualities and modern aesthetics can be employed to deliver comfortable internal environments for all

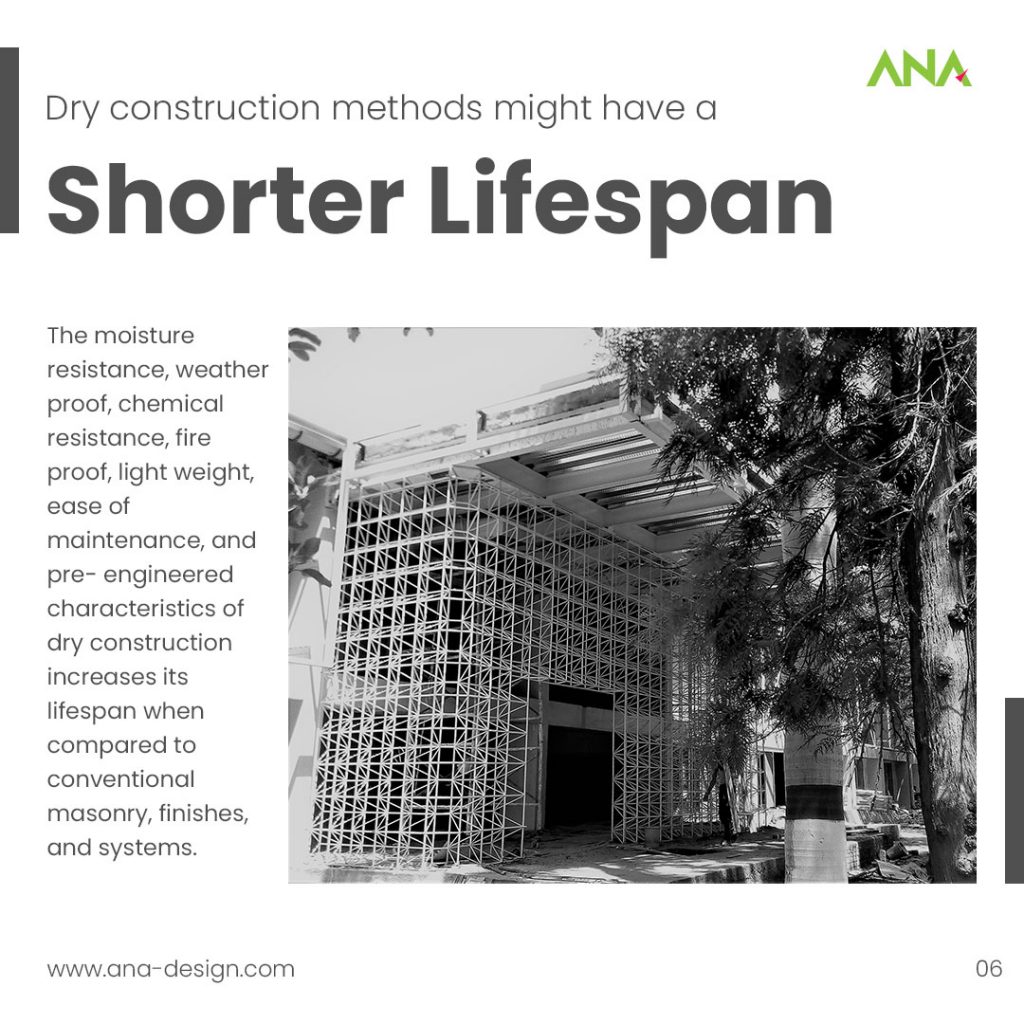

5. Dry Construction methods might have a

Shorter Lifespan

The moisture resistance, weather proof, chemical resistance, fire proof, light weight, ease of maintenance, and pre-engineered characteristics of dry construction increases its lifespan when compared to conventional masonry, finishes, and systems.

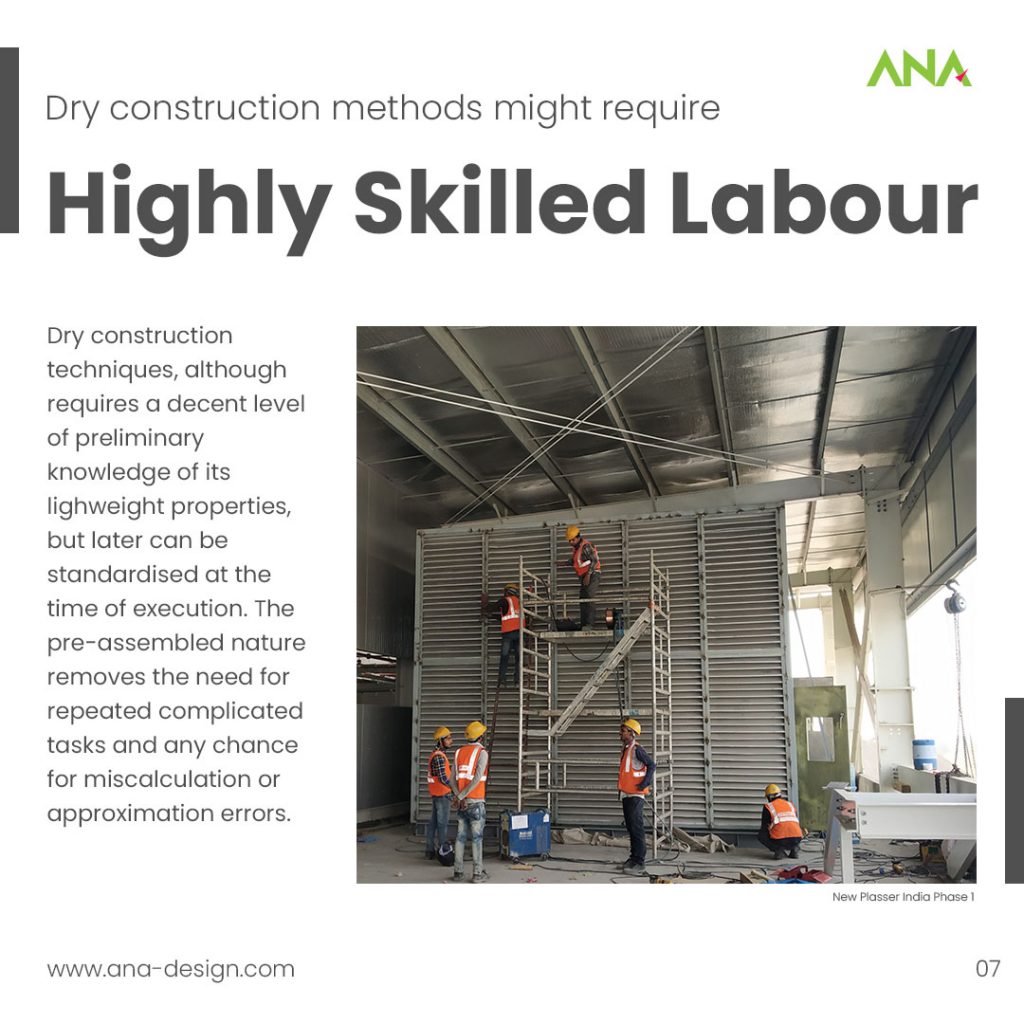

6. Dry Construction methods might require

Highly skilled Labor

Dry construction techniques, although requires a decent level of preliminary knowledge of its lightweight properties, but later can be standardized at the time of execution. The pre-assembled nature removes the need for repeated complicated tasks and any chance for miscalculation or approximation errors.

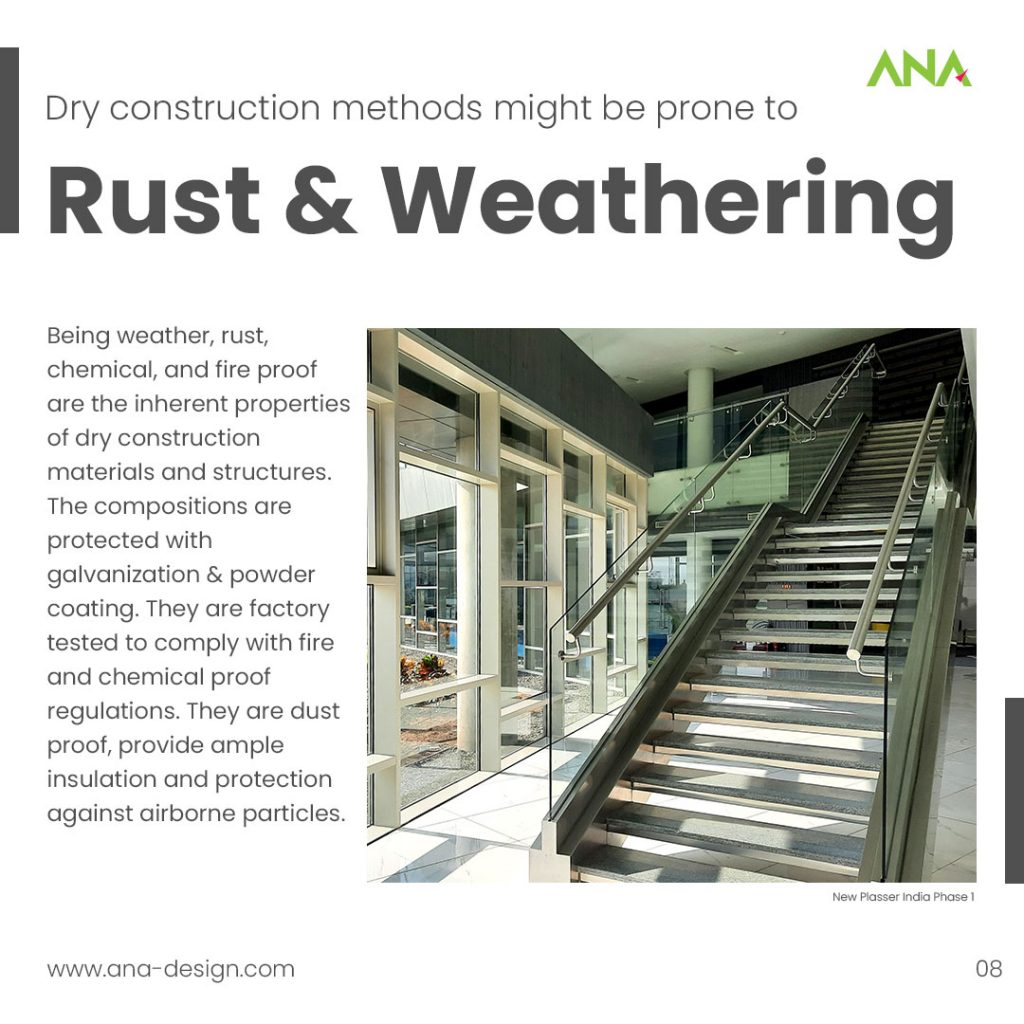

7. Dry Construction methods might be prone to

Rust and Weathering

Being weather, rust, chemical and fire proof are the inherent properties of dry construction materials and structures. The compositions are protected by galvanization and powder coating. They are factory tested to comply with fire and chemical proof regulations. They are dust proof, provide ample insulation and protection against airborne particles.

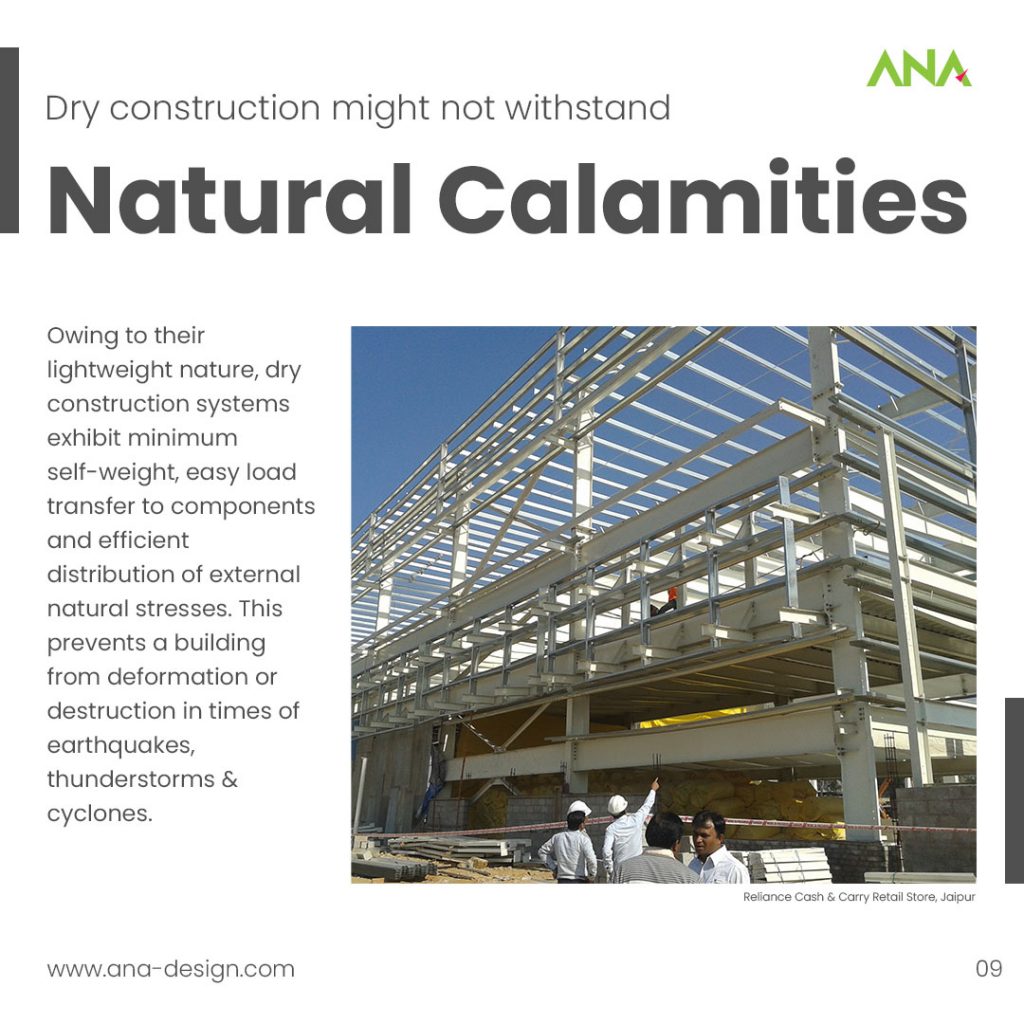

9. Dry Construction methods might not withstand

Natural Calamities

Owing to their lightweight nature, dry construction systems exhibit minimum self-weight, easy load transfer to components, and efficient distribution of external natural stresses. This prevents a building from deformation or destruction in times of earthquakes, thunderstorms, and cyclones.